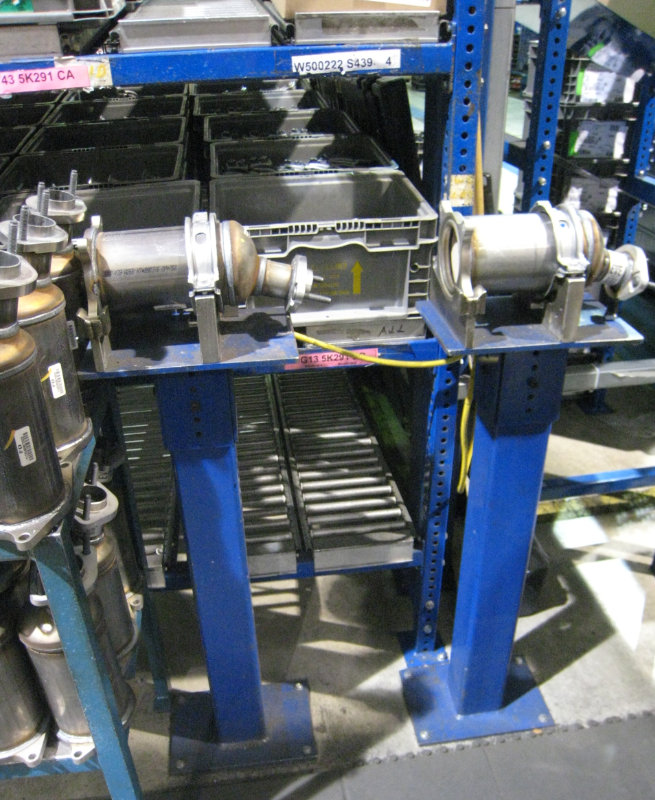

Buck build fixtures are static fixtures used for assembling or modifying parts at a single station.

Features

Buck build fixtures are tooling fixtures mounted directly to the floor or to a movable cart. They are a combination of custom nests, supports, locks and clamps designed to hold a part or multiple parts, utilizing adaptive tooling. Fixtures have rotation and locking features depending on the requirements of the assembly build.

Benefits

Below is a list of the many benefits of buck build fixtures:

- Tooling is custom designed to hold unique parts

- Adaptive tooling holds more than one part

- Parts are guided for easy loading and unobstructed for easy unloading

- Parts are held firmly to withstand basic assembly forces

- Clearance is provided to ensure access for secondary components and fastening tools

- Fixtures rotate (as required) in any and all axes X, Y and Z for improved part access

- Rotating fixtures are balanced to reduce the force required to rotate the part

- Fixtures are directly mounted to the floor for static stations, or mounted on a movable cart when used in more than one location

Applications

Buck build fixtures are commonly used for low volume or high cycle time part builds, repairs, tests or prototyping where conveyor systems are not justified.

Related

Buck Build

Buck build fixtures are static fixtures used for assembling or modifying parts at a single station. Features Buck build fixtures are tooling fixtures mounted directly to the floor [...]

Assembly Line Fixturing

Assembly lines are commonly used for assembling complex items such as automobiles, aircraft, household appliances and electronic goods. Parts that are assembled on those lines typically require support during the assembly process in custom fixtures. [...]

Lift Assists & End Effectors

Magnum provides custom ergonomic lift assists to improve operator safety, quality and productivity. End effectors are custom designed to suit each product and associated assembly tooling and dunnage. Features [...]