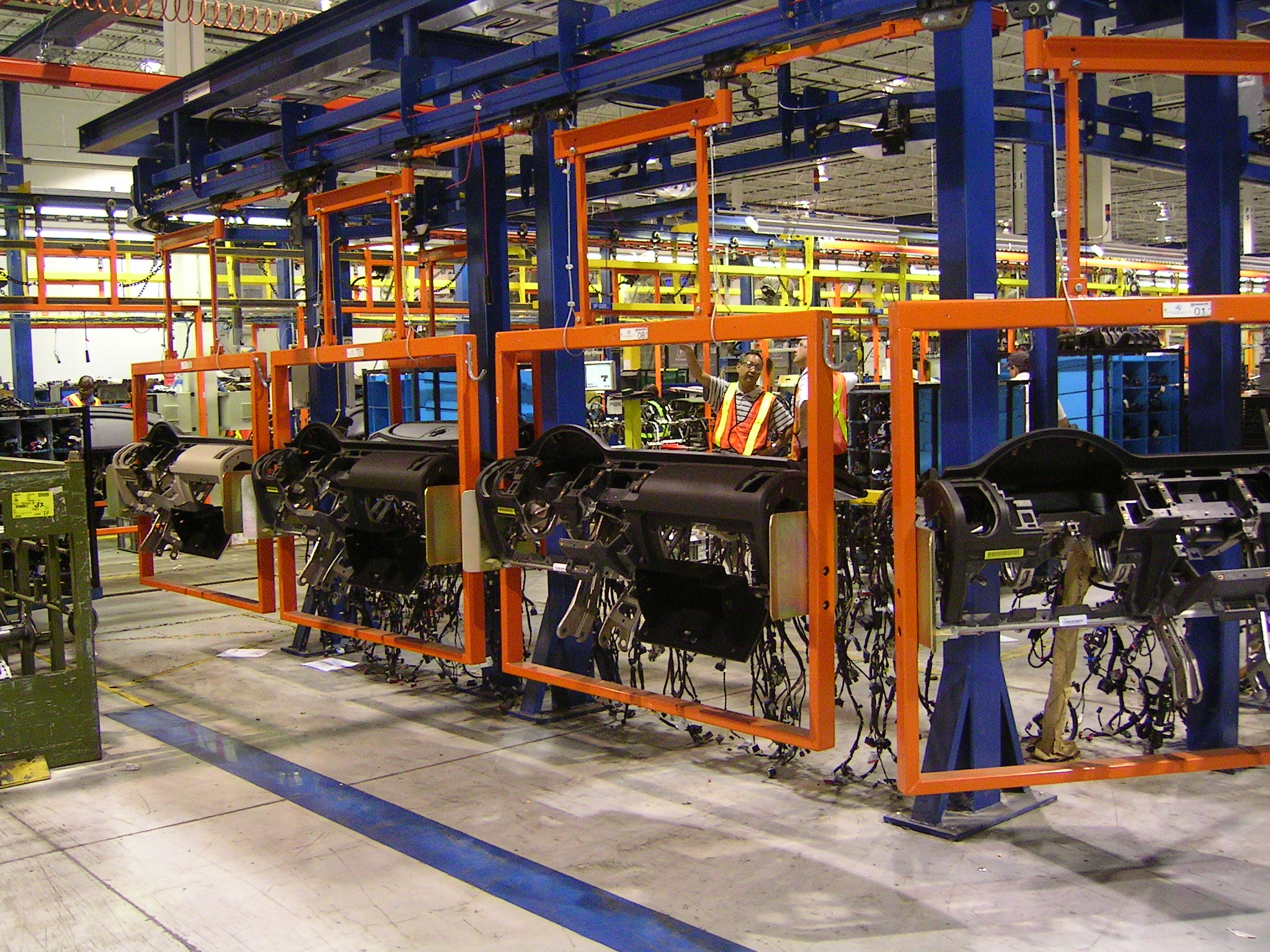

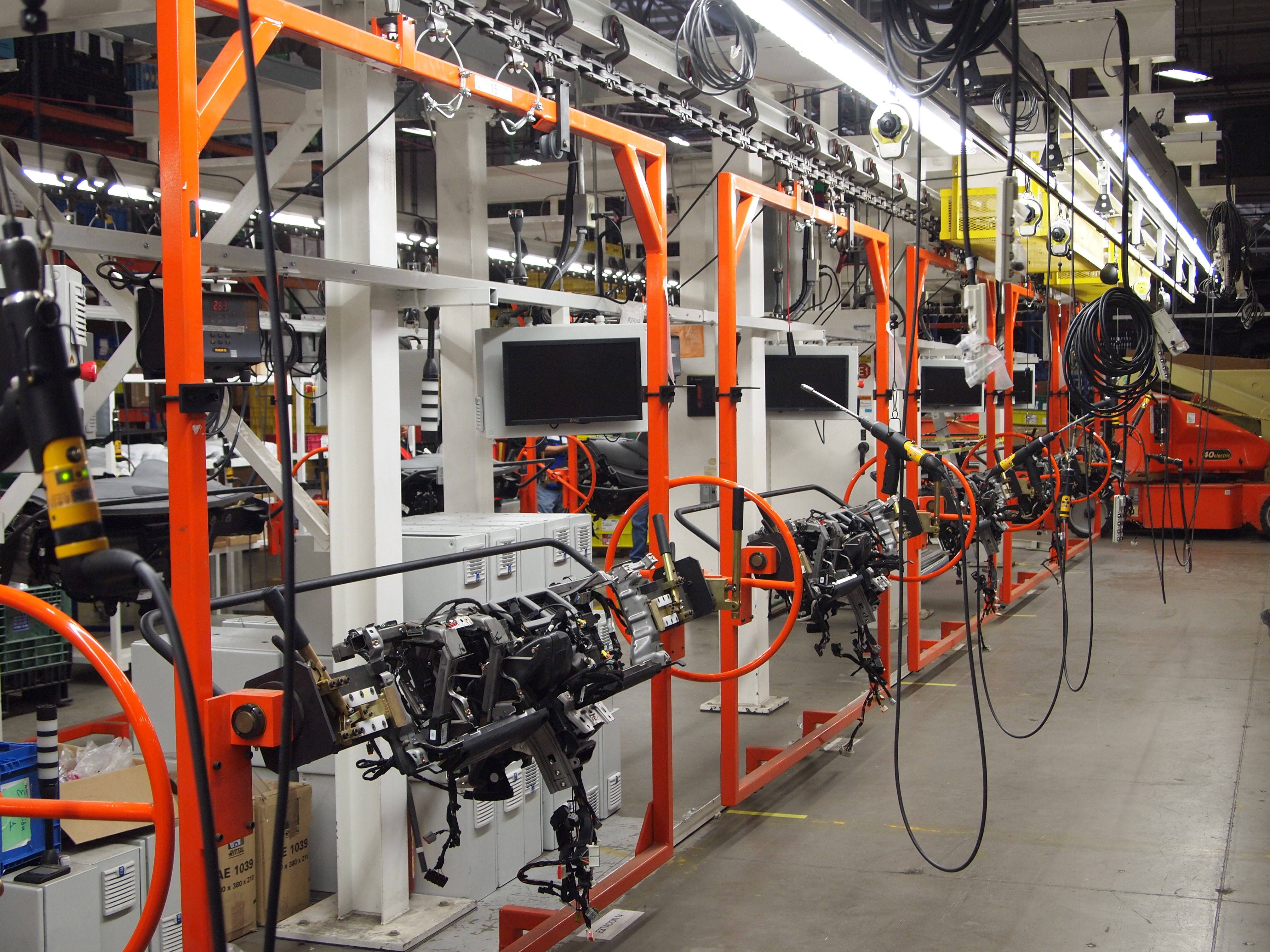

Instrument panels (IPs) and cockpits are high content modules that are ideally built on overhead continuous chain or power and free conveyor systems and supported intensively with dedicated secondary equipment. These systems allow suppliers to the automotive OEMs to produce and supply IPs and cockpits reliably with extremely short (~45 second) cycle times.

Productivity

IP and cockpit assembly builds are complex and demanding as components are assembled from many sides of the product. Our ergonomic carriers feature a 360° trunnion with minimal end tooling, which allows all-around access, for assembly and fastening. The trunnion height is set during the prototyping phase, to suit the process and the assemblers’ ergonomic needs.

Synchronous overhead conveyor offers management complete control of their lines throughput by pacing the line with a fixed line speed. For more demanding builds, power and free overhead conveyor offers multiple paths and chain speeds for multi-lane electrical testing, inspection and repair.

Customized

Complete systems come with custom designed and built ergonomic lift assists, which integrate seamlessly with the carrier tooling and the inbound and outbound racking holding features. Conveniently positioned tool rail locates nut drivers and screw guns optimally for operators at each station. Systems are supported with heavy duty overhead structures, which are design to also support accessories such as fans, lights, error proofing stations, torque controllers, printers, routers, HMI’s, scanners and signs.

Features

Our IP/Cockpit assembly lines feature:

- Synchronous or power and free overhead conveyor systems

- Custom fixtures with 360° rotation (carriers/trunnions)

- Heavy duty support structure

- Non-binding and long life overhead guide rails

- Tool rail

- Area lighting and fans

- Redundant drives

- Full controls package with VFD motor control, HMI, call buttons, beacons and emergency stops

- Continuity and full functionality electrical testing rigs

- Cranes, articulating arms and lift assists

- Rack transfers and rack over/unders

- Feeder conveyors and bin tilters

Related

Floor

Floor conveyor systems are used widely as delivery and storage systems for their range of capacities, robustness and cost effectiveness. Features Floor conveyor system designs vary significantly with [...]

Overhead

Overhead continuous chain or power and free conveyor systems are used widely as delivery and storage systems for their versatility, robustness and cost effectiveness. Features Power and free [...]

Gravity

Gravity conveyor systems are the most economical method of conveniently storing and delivering light weight parts. Many traditional conveyor systems are suitable and reconfigurable to work utilizing gravity. Economical [...]

AGV/AGC Assembly Line

Magnum’s Automatic Guided Vehicles (AGVs) and Automated Guided Carts (AGCs) are manufactured by the industry leader; Daifuku North America (JB Webb). These vehicles increase productivity, reduce operating costs and improve ergonomics for many industries [...]

AGV/AGC Material Delivery

Magnum’s Automatic Guided Vehicles (AGVs) and Automatic Guided Carts (AGCs) are manufactured by the industry leader; Daifuku North America (JB Webb). These vehicles increase productivity, reduce operating costs and improve ergonomics for many industries. [...]

Floor

Floor conveyor systems are used widely throughout the manufacturing sector due to their range of capacities, robustness and cost effectiveness. Streamline Floor conveyor systems streamline a manufacturing process [...]